“LIVE” AT ALL TIMES

Change is the only constant feature on the electronics market. High innovation pressure leads to spectacular new developments and technology updates at ever shorter intervals. In order to obtain the necessary permits, strict criteria for product quality and safety have to be satisfied – and that generally not only for the German and European market, but also for the hotly contested international markets, in particular North America and Canada. In addition to the normal values such as current density, interference emission and electromagnetic compatibility, all the other characteristics such as length, diameter, material thickness and gaps have to be examined, measured and verified with high precision. Tailor-made measurement technology from Schneider Messtechnik supports you in this work – precisely, reliably and cost-effectively.

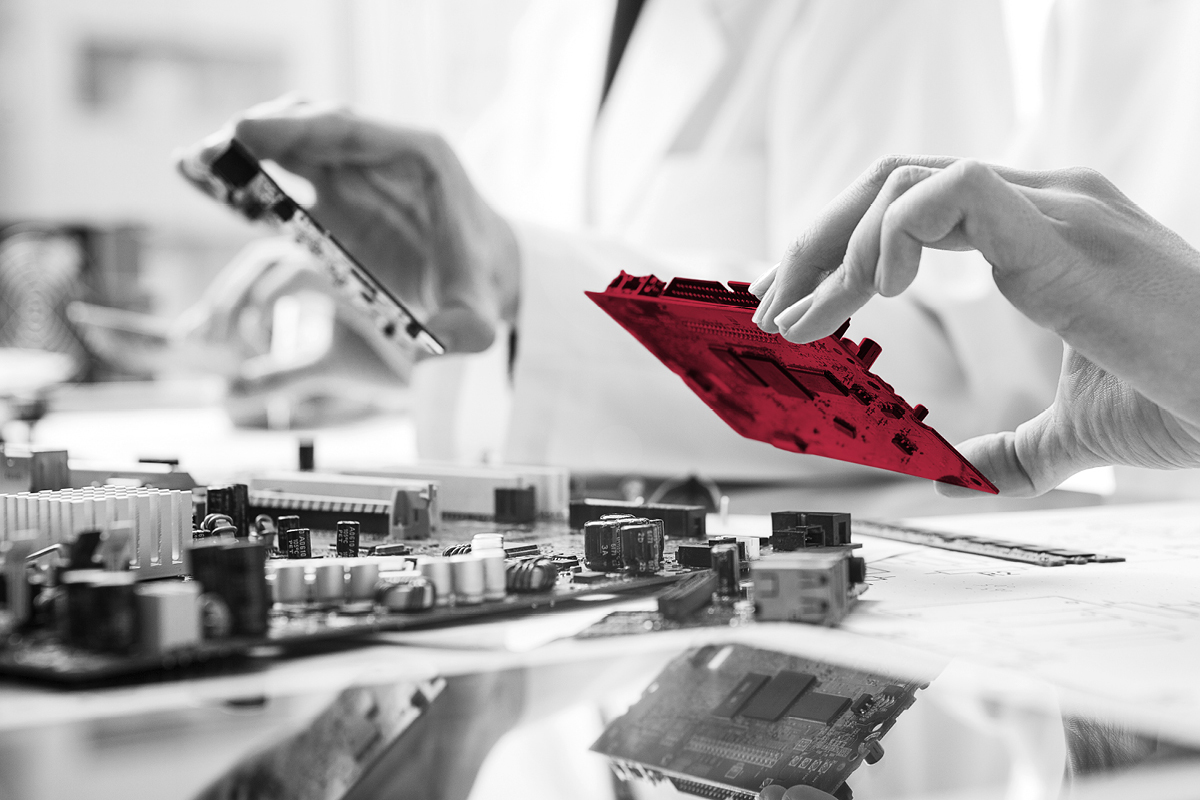

Precision in every size

Schneider Messtechnik offers you the highest precision in all relevant sectors. No matter whether you are producing complete product batches or further processing individual components. From the smallest plug contact through printed circuit boards with ultra-narrow gap width up to 200 cm LCD screens – you can measure and evaluate all the necessary parameters reliably and precisely and document them in detail as proof for approvals authorities and your customers. Our 3D multisensor coordinate measuring machines of cost-effective gantry design, in particular, have been proven here for many years. Thanks to their outstanding optical properties and versatility, they can be used universally. The dust-protected precision guides allow measurements to be carried out even in sensitive production areas. And the compact granite design guarantees long-term measurement accuracy and stability even in the most rugged production processes.

Designed to withstand toughest conditions

Especially Schneider 3D multi-sensor coordinate measuring machines have proved their worth in the electronics industry for many years. They feature an efficient portal-type design and are fit for universal use due to their outstanding variety of optical features. Dust-protected precision guides enable measurements to be performed even in sensitive production areas, while the solid granite construction of the machines ensures long-term stable measuring accuracy, even in harshest production environments.